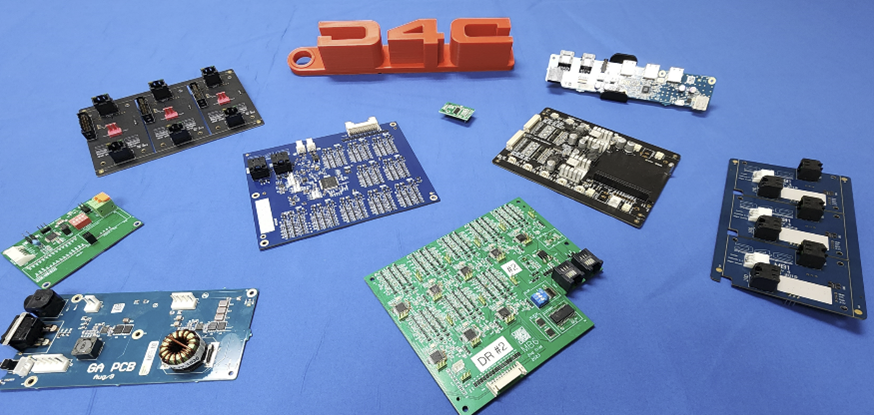

Prototyping

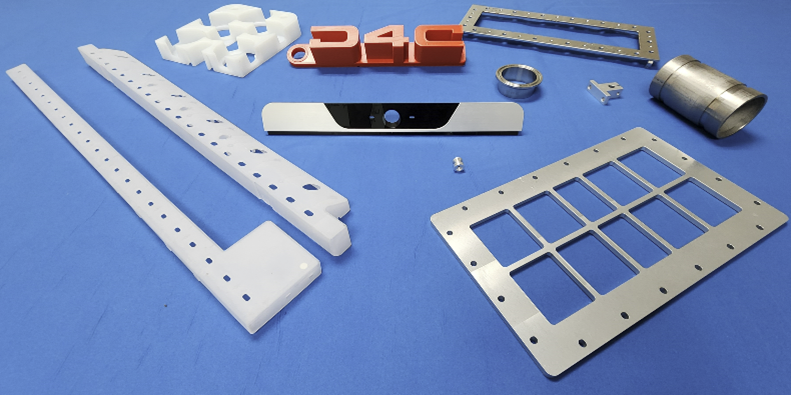

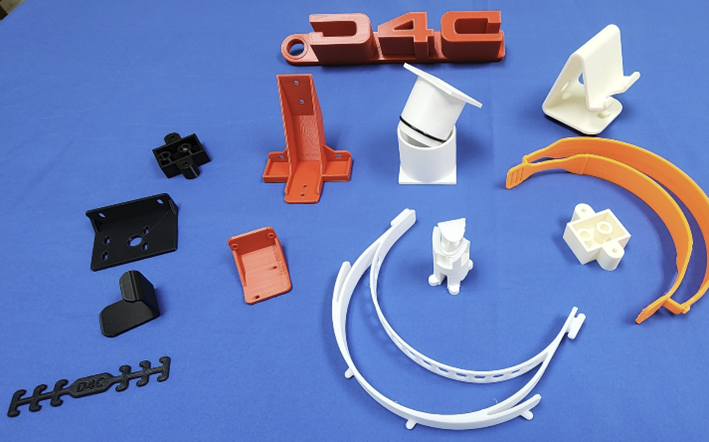

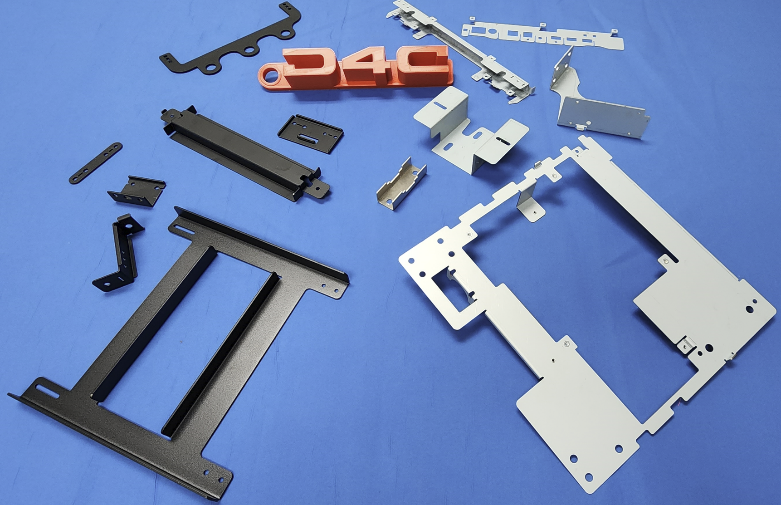

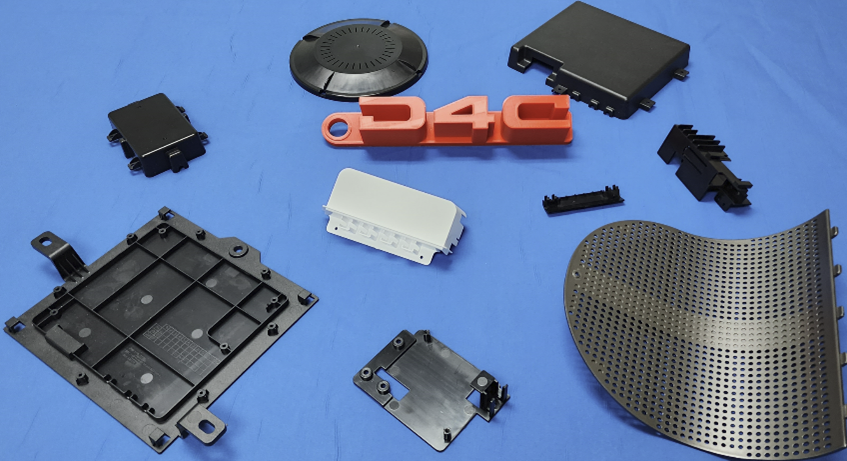

At D4C Product Development, we specialize in transforming innovative concepts into tangible realities. To achieve this, we go through our comprehensive prototyping services. We provide prototyping services for mechanical, electrical, and software systems. Our services include 3D printing, CNC machining, Sheet Metal, Injection Mold, PCB, wiring and embedded systems development.

Our dedicated team of engineers meticulously crafts and refines prototypes, enabling you to visualize and test your designs with precision. We can help you bring your ideas to life quickly and efficiently, and we work with you every step of the way to ensure that your prototype meets your needs. We bring your visions to life, ensuring a seamless transition from prototype to production.

At D4C we have an extensive supply chain that works along us to provide you with the best service regarding your prototyping requirements and needs.